FLOW.CONTROL & FLOW.MATIC

Lowest material input amount. Most precise geometry of the profile.

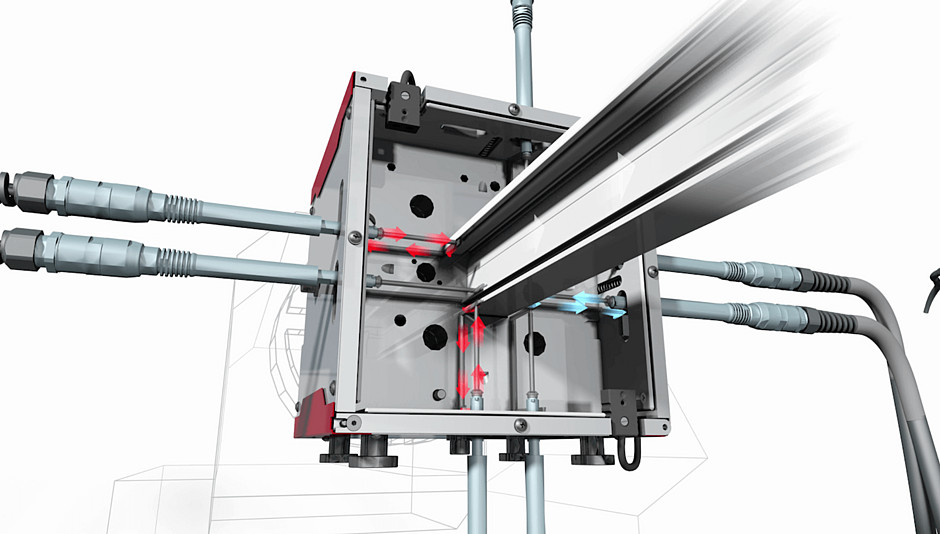

FLOW.CONTROL enables sustained production improvement. The melt flow is controlled directly in the die using precise temperature control. That results in constant profile dimensions and production close to the lowest profile weight tolerance.

Your benefits:

- Minimised input amount

- Precise profile sections

- Secured reproducibility

- Faster start-up process

- Lower production costs

With FLOW.MATIC – the further development of FLOW.CONTROL – the functional dimensions of the profile sections can now be permanently ensured, fully automatic and within seconds.

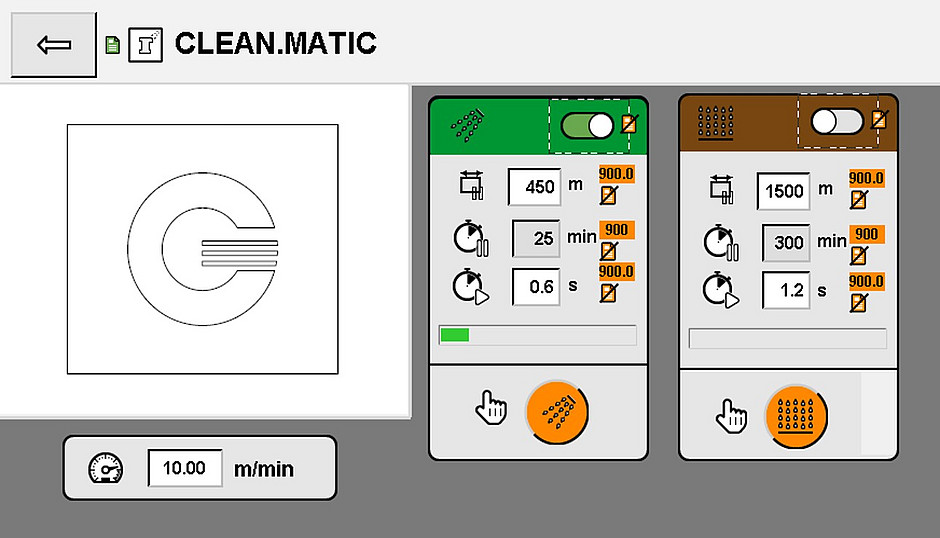

CLEAN.MATIC

Eine saubere Sache.

CLEAN.MATIC automatisiert die Reinigung der Trockenkalibrierung in der Produktion – der Schrottanteil und der Reinigungsmitteleinsatz reduzieren sich deutlich. Mithilfe der im Linienrezept voreingestellten Reinigungsintervalle und Zykluszeiten, werden weiche Ablagerungen am Trockenkaliber höchst effizient und effektiv entfernt.

Ihre Vorteile:

- Keine Beschädigung des Profils beim Reinigen der Vollprofilsektionen – kein Schrott!

- Automatische vorbeugende Reinigung ohne Personalaufwand

- Biologisch abbaubares Reinigungsmittel schont die Umwelt

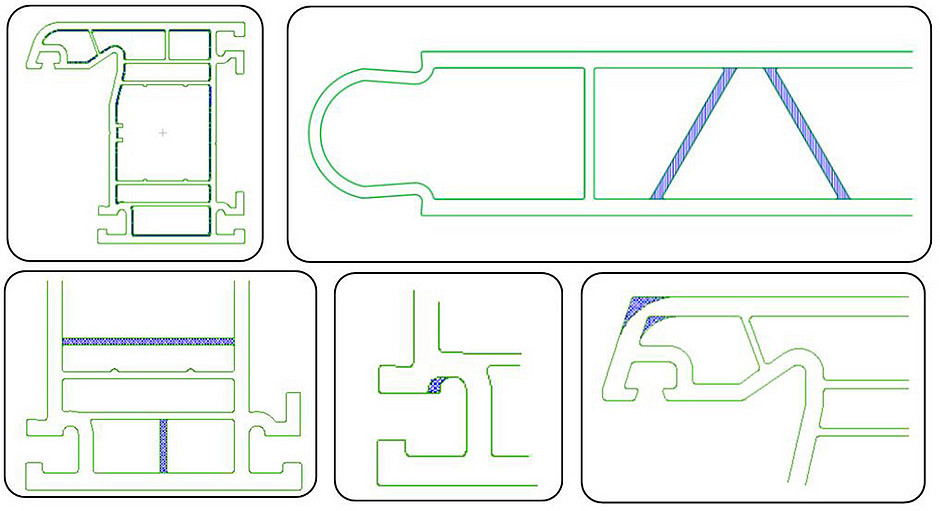

Changes to the geometry of the profile

Use our know-how to boost your success.

Is the wall thickness of your profile too thick, causing problems in your production? Are profile dimensions exceeding the tolerance, causing problems with functionality? In most cases, it is possible to modify your existing extrusion tooling to once more adapt it to the required market requirements or quality standards. The optimisation of the geometry of the profile often goes hand in hand with a reduction in production costs. Seize this opportunity!

Minimum weight of the profile

Safely produce close to the lowest tolerance limit.

The input material is the main cost driver in the extrusion process, which is why the leverage for reducing profile costs is correspondingly high. Reducing the profile weight of a typical large main rotor by just 1% can save 15 tonnes of material – each and every year.

Together with us, you can define all tolerances and the minimum weight of the profile: we guarantee that we can significantly reduce your input material in the profile by complying exactly with the tolerance specification.