Simple, fast and error-free changeover.

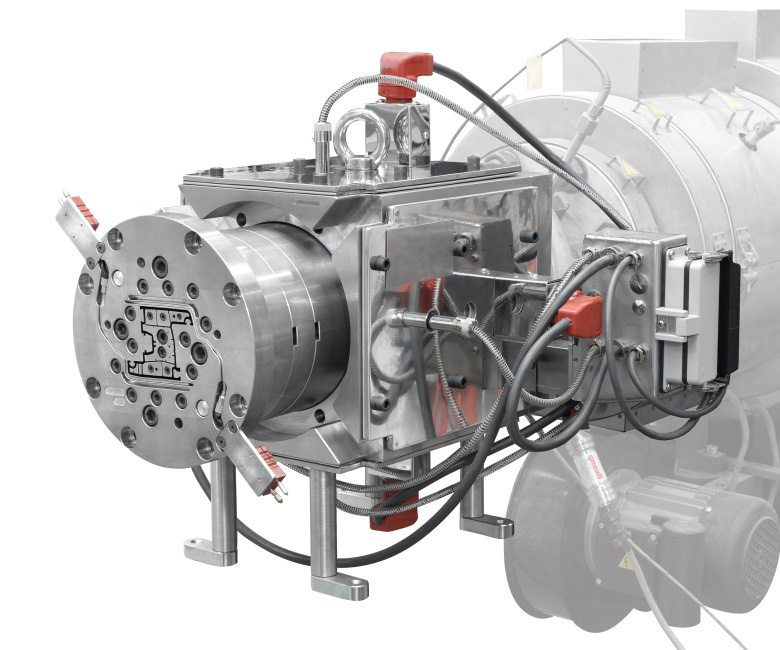

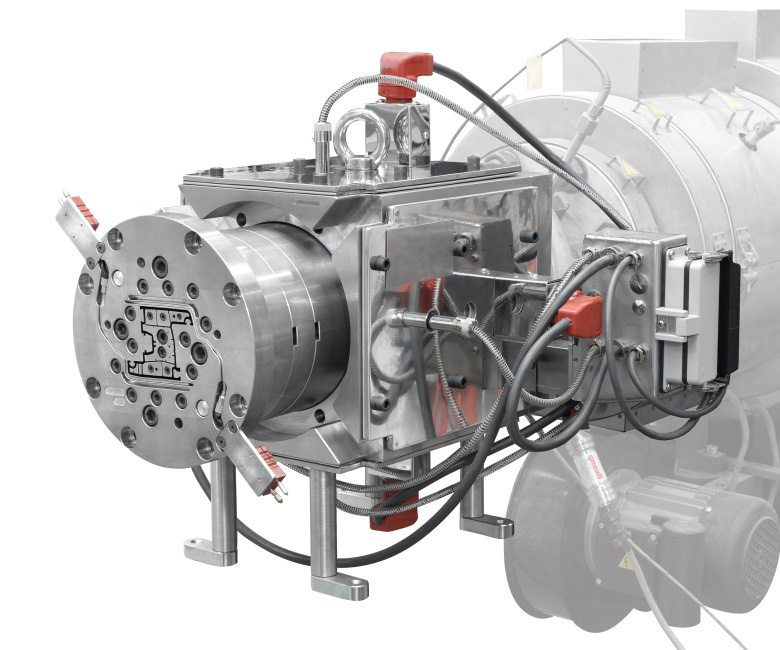

Standard die housing

The EVO.TOOLING system represents the evolution of the medium performance range and combines high-quality profiles with an attractive price. Decades of expertise from the premium sector and our proven quality from Europe form the basis of this redefined tooling concept. With EVO.TOOLING, you benefit from an exceptional combination of economy and precision.

Various options possible

Standard die housing

Interchangeable die inserts