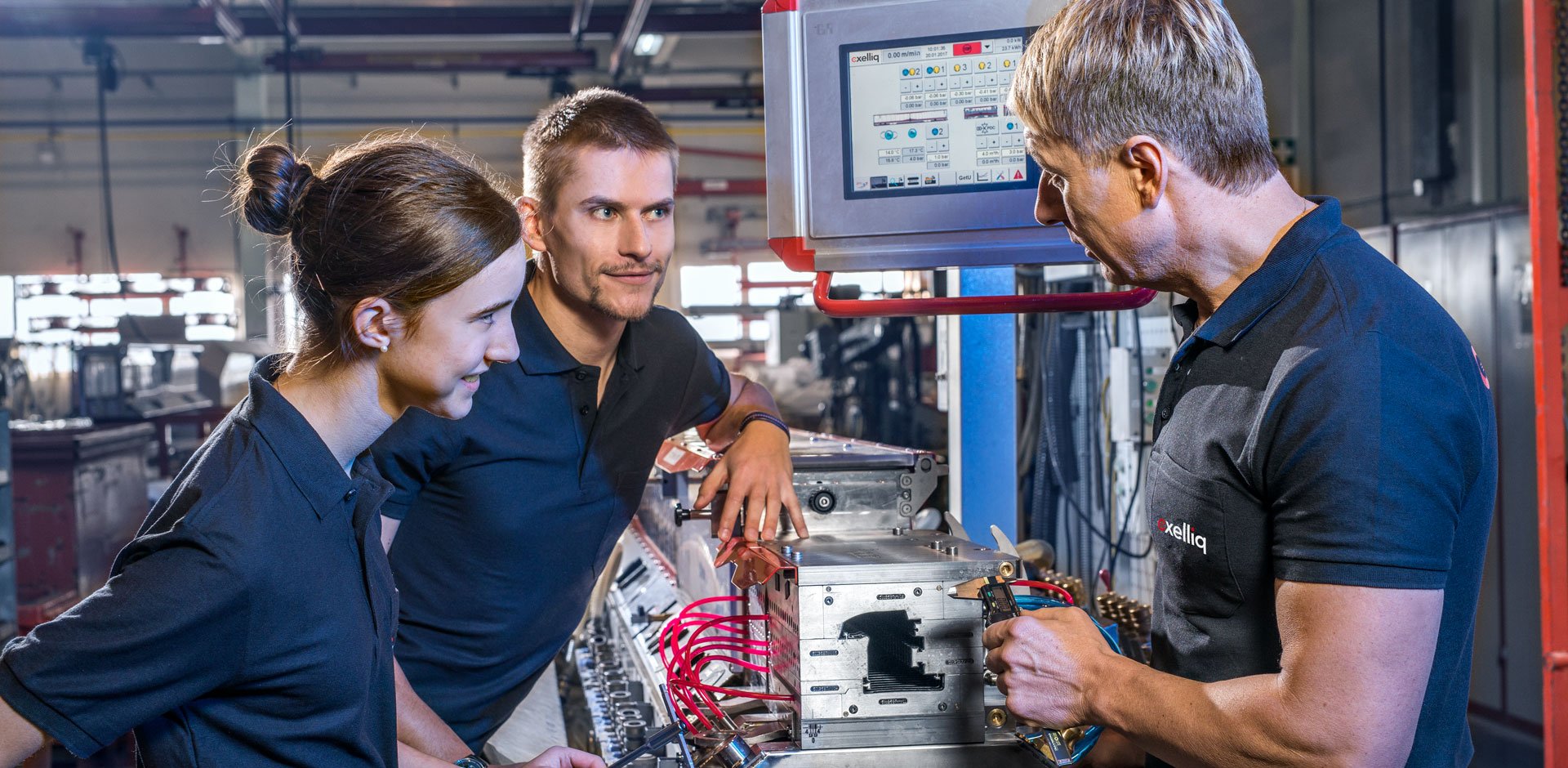

Training modules

Rising key performance indicators and increasing quality and productivity requirements increase the need for expertise. Whether the employee is a novice or has experience – the modular training programme is adapted to the individual requirements of the participants. Because only well-trained employees can operate theirextrusion linesat maximum capacity. All theoretical and practical parts can be held at your company or at Exelliq's premises.

How you benefit:

- Different training levels

- Individual training structure

- Dedicated trainers with decades of experience

- Changeable course length

- On-site training at your location or at our premises

- Training materials

Line operator

Exelliq's line operator training enables you to increase your staff's understanding and competence in operating extrusion lines and handling tooling systems. You decide whether you want to have the training performed at your company or at Exelliq’s premises.

Training session content:<br/> Window systems I PVC material (Basic) I Tooling systems I Tooling production I Machine operation (Theory) I Quality control I Procedures I Test runs I Lab I Finite elements (Basic) I Downstream training (Exelliq Downstream) I Die assembly/cleaning I Calibration assembly/cleaning I Troubleshooting I GetU environment analysis I Tooling storage I Tooling documentation

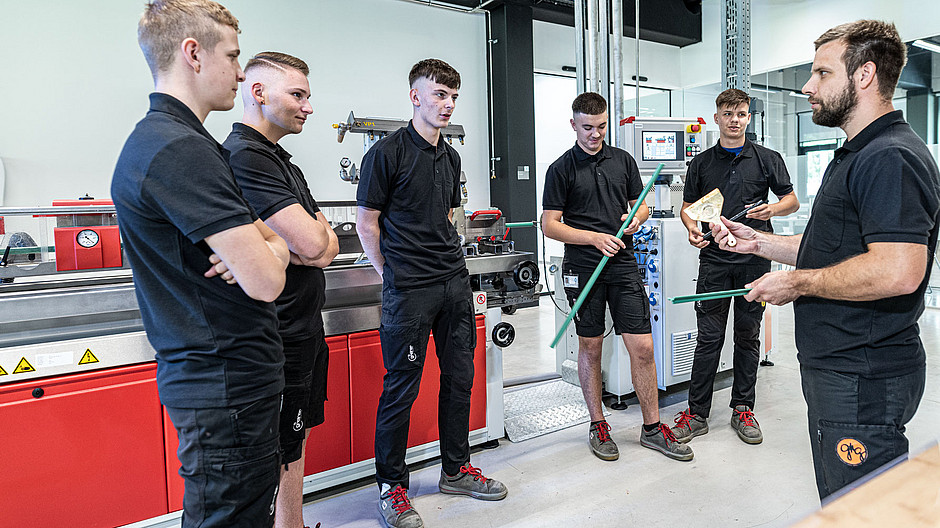

Tooling maintenance

To increase the understanding of and competence in the maintenance of Exelliq tooling systems is the objective of all tooling maintenance trainings. All theoretical and practical parts can be held at your company or at Exelliq’s premises. It is your decision.

Training session content:<br/> Tooling systems I Tooling production I Finite elements (Plus) I Die assembly and cleaning I Calibrator assembly and cleaning I DigiOM I Tooling storage I Spare parts storage I Machinery I Small repairs* I Milling* I Welding* I Filing* I Polishing I Tooling documentation

* Toolmaking experience required

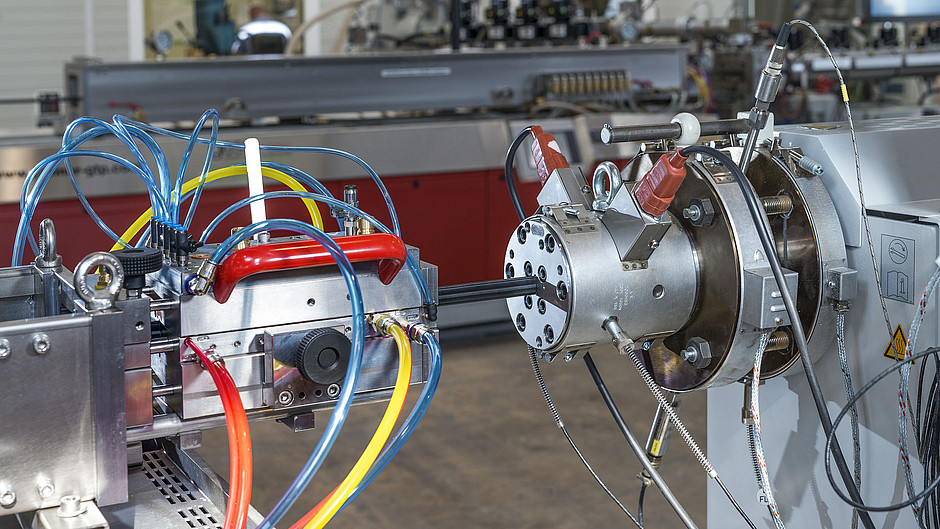

Profile and tooling analysis

Exelliq also offers training for tooling/profile analysis. Thorough analysis know-how is one important step in optimising all extrusion processes.

Training session content:

Sample collection I Flow and profile analysis I Tooling inspection I Reporting I Digi-Om I Identification and determination of root causes and confirmation I Measures and goal orientation