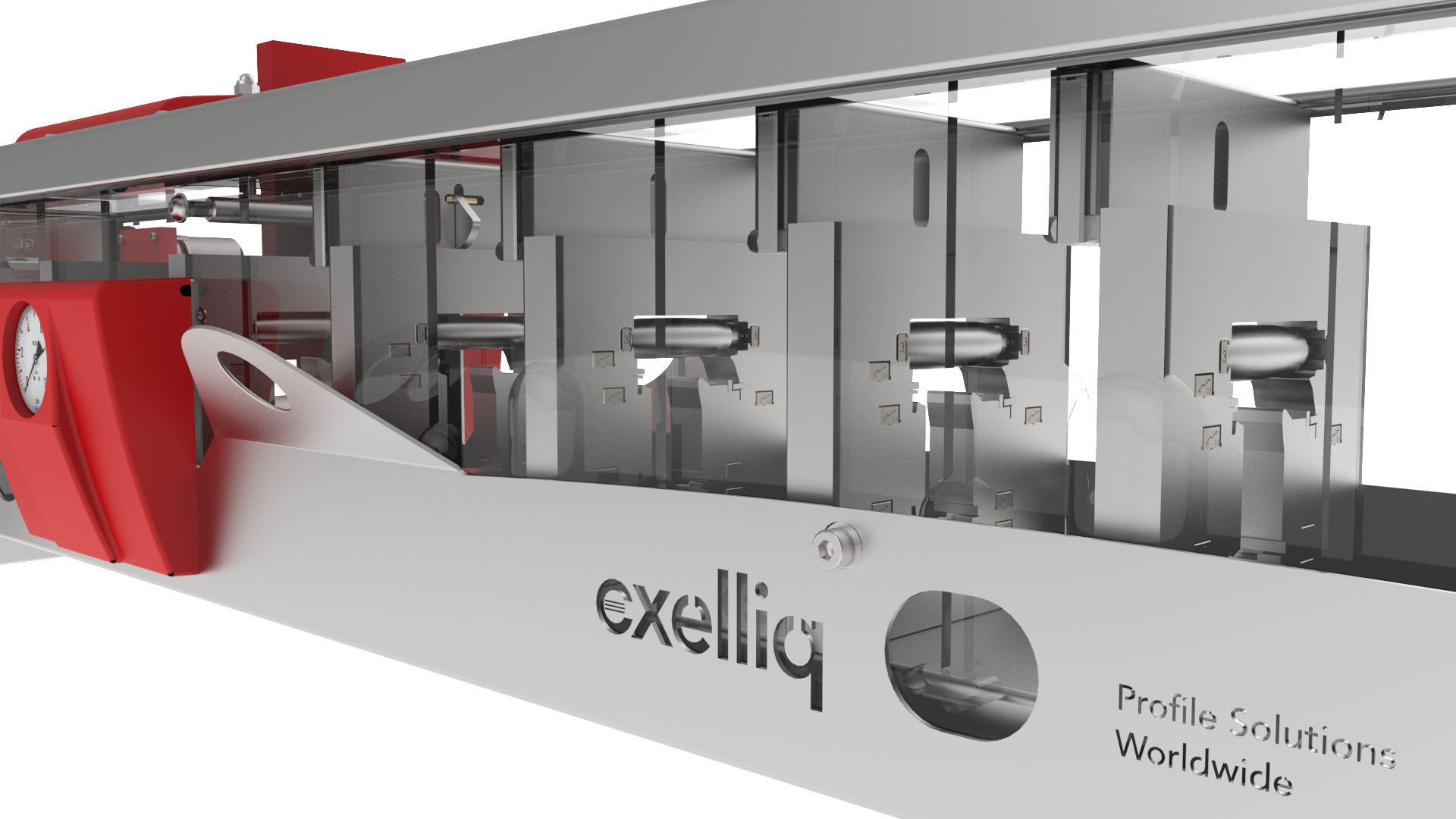

EVO.TOOLING by Exelliq (Former Greiner Extrusion) is a high-performance, cost-efficient extrusion tooling system designed for manufacturers seeking precision, reliability, and flexibility. By integrating premium-sector expertise with European quality standards, EVO.TOOLING delivers superior results at an attractive price.

Key advantages:

✅ Fast production cycles with minimal downtime

✅ Attractive price for high-quality profiles

✅ Low scrap rates for cost efficiency

✅ Digital documentation for seamless maintenance

✅ Modular upgrades to enhance performance

✅ Rapid delivery – first profile samples in just twelve weeks

A New Era of Tooling Excellence

Designed for reliability and efficiency, EVO.TOOLING outperforms traditional solutions with state-of-the-art design and manufacturing. It combines high-quality profiles with a cost-effective approach, enhancing production capabilities while maintaining a stable cost structure.

Speed and Reliability for Maximum Efficiency

Time is money—EVO.TOOLING minimizes downtime and maximizes efficiency. High repeat accuracy enables fast start-up times, while low scrap rates extend tooling lifespan and reduce maintenance costs. First profile samples are available in as little as twelve weeks.

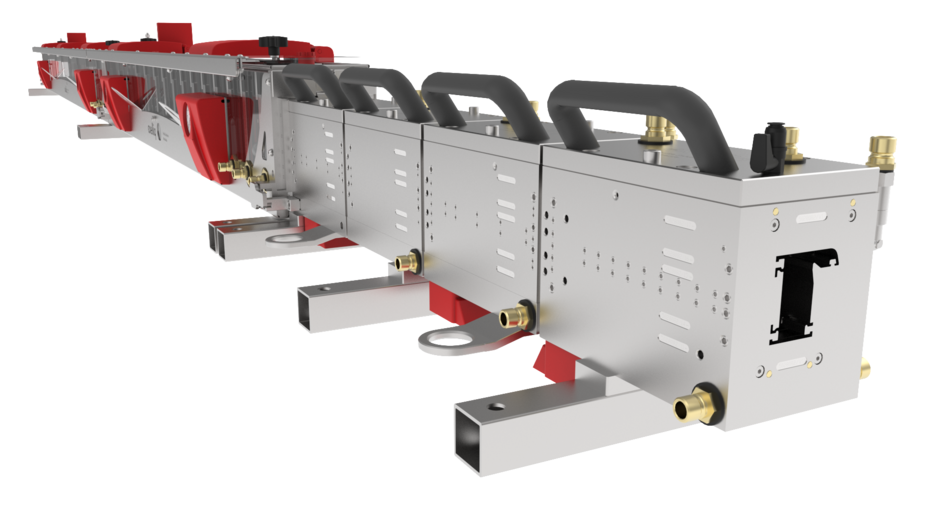

Seamless Digital Documentation and Maintenance

Fully digital documentation ensures precise component tracking and simplified maintenance. The ‘plug & produce’ approach allows easy spare part replacement, reducing downtime and maximizing productivity.

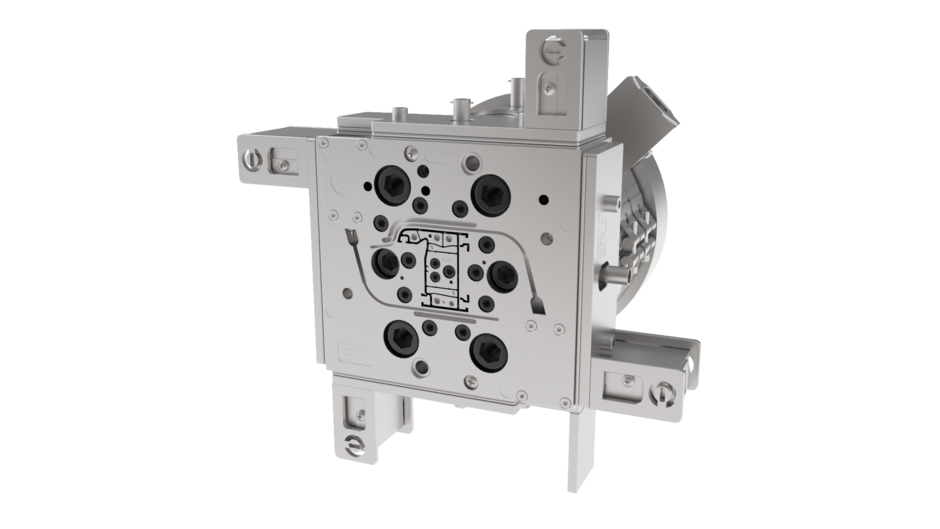

Customizable Upgrades for Enhanced Performance

The modular design enables seamless upgrades from the premium sector, such as the Heater Cage for optimal temperature stability, Air Support Control for improved material handling and the FLOW.CONTROL function, which enhances material distribution and precision.