Exelliq Group presented its latest innovation to the professional public at FAKUMA, the world’s leading fair for industrial plastics processing. Exelliq’s extrusion lines are synonymous with profile extrusion all over the world. Exelliq Group is on the path to successful automation and is already offering very efficient systems for controlling extrusion lines. With systems like FLOW.CONTROL, air support control and GESS.tronic, max precision in geometric dimensions and significant material and energy savings can be achieved.

The demands placed on profile extrusion are constantly growing in sophistication and complexity – be it for profiles for windows and doors or for the broad field of technical applications with very diverse materials. On the side of the technology and plant supplier, this requires process expertise that is equally broad and deep, a thorough understanding of customer needs, and strong innovative capabilities. A comprehensive range of services is offered – from formulation to the construction of turnkey extrusion plants. In partnership with the customers, tailor-made solutions are generated. The development of innovative solutions and cutting-edge technologies has greater benefits for customers: more attractive profile surfaces, more precise contours, reduced material usage, greater machine availability, more reliable processes, shorter tooling and maintenance times, lower costs per running metre of profile and lower overall operating costs.

Exelliq's extrusion systems cover the full scope of applications for plastic profiles, specialising in windows & doors, technical profiles, cable ducts, WPC profiles, foam profiles, lighting systems, swimming pool covers, rain gutters, and much more.

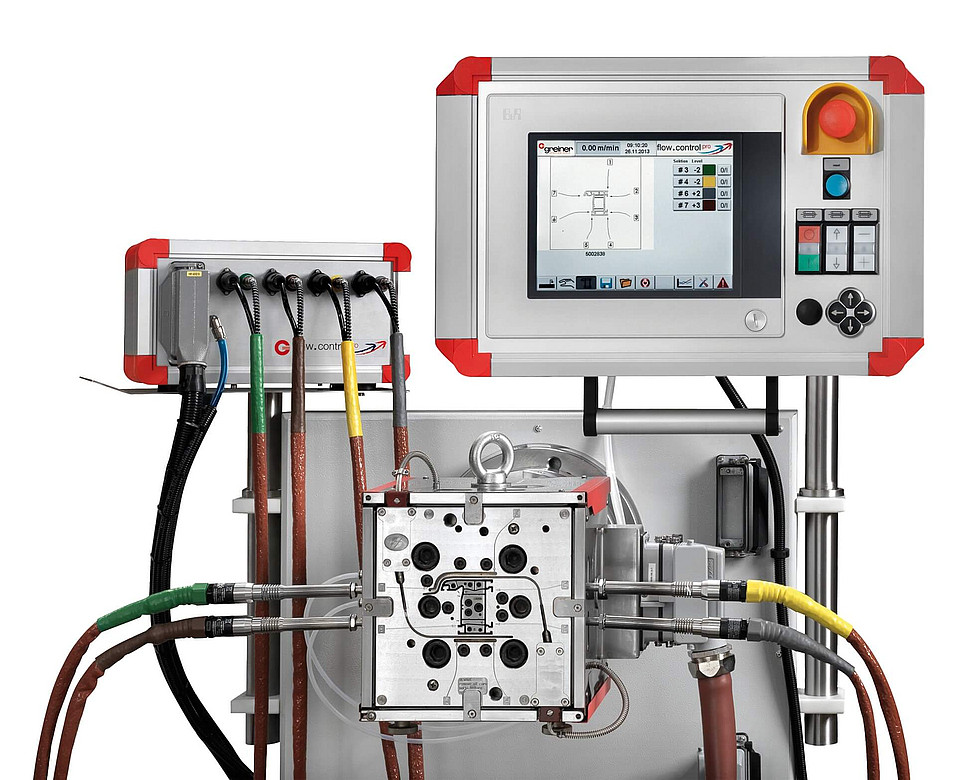

FLOW.CONTROL provides precise functional dimensions and reduces costs

With FLOW.CONTROL, an innovation from the Exelliq Group, individual profile sections are decelerated or accelerated selectively with cold or hot air through control of the melt flow. With FLOW.CONTROL, minimal input material, precise functional dimensions and shorter start-up times are guaranteed. The additional control possibility increases line flexibility, and the reaction/intervention time in the event of environmental variations is reduced significantly. It is possible to retrofit FLOW.CONTROL in most of our die concepts.

FLOW.CONTROL enables section-by-section control of material flow rates, fast response time to deviations, better operability and reproducibility of all settings.

With FLOW.CONTROL, start-up times are shortened and the scrap rate is reduced. The high process reliability and the extended production cycle keep the plants in production for a longer time.

NEW: The co-extruder CE-22 special machine

for high flexibility and process reliability in production.

Multi-layer co-extrusion is now used in many profile applications. Intelligent hybrid solutions with innovative material combinations and the use of recycled materials guarantee performance tailored to the application. Multi-layer co-extrusion makes it possible to meet various requirements perfectly from both an economic and a technical point of view. The Exelliq systems are adapted perfectly to the jointly developed formulation.

With the newly developed co-extruder CE-22, a minimal output of up to 0.3 kg/h can be achieved. This is especially necessary when producing profiles with a high level of detail, such as for the co-extrusion of small gaskets.