The Exelliq Group accepted AMI's invitation to present a lecture on "Innovation and sustainability in plastic profile extrusion" at the "Profiles 2017" international conference, which was held from 19-20 September 2017 in Cologne. Wilhelm Dieterstorfer, area sales manager at Exelliq Austria GmbH, presented to the public the current simulation tools used at Exelliq Group as well as the advantages of the various COEX technologies and their positive impact on the sustainability of profiles generated therefrom.

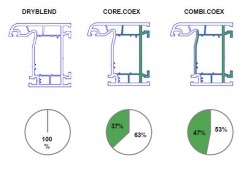

Co-extrusion is now used in many profile applications. Intelligent hybrid solutions with innovative material combinations and the use of recycled materials guarantee performance tailored to the application. Co-extrusion makes it possible to meet various requirements perfectly from both an economic and a technical point of view. Many applications can no longer do without recycled plastics. What is more, new recycling technologies continuously improve the quality of the materials available on the market. The Exelliq COEX systems are adapted perfectly to the jointly developed formulation.

Furthermore, the FLOW.CONTROL function was explicitly considered to ensure functional dimensions, material savings, and increase net production times.

The AMI conference highlighted current market trends and offered an overview of the state of extrusion technology. Approximately 100 international participants made it a very successful event. Exelliq Group drew enormous interest thanks to its innovative capacity, while conveying its notable efforts in sustainability.