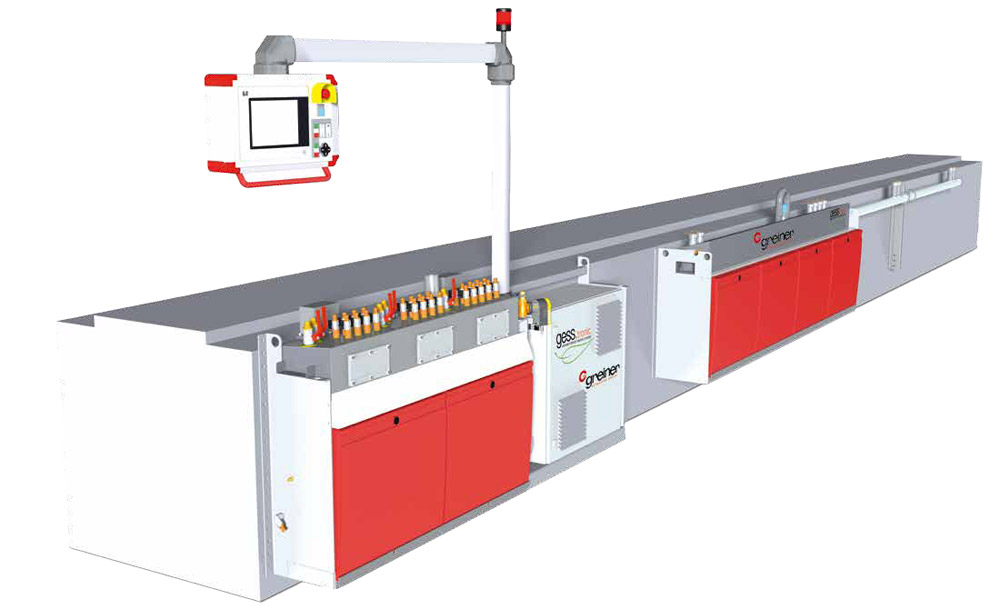

GESS.tronic – the energy saving system for professionals

The majority of energy in profile extrusion is used up by the vacuum pumps in the calibration table. By controlling these pumps based on demand and using side-channel compressors for emptying tanks, GESS.tronic reduces energy consumption by up to 90%. GESS.tronic is available as an option for RED.CAL and can be retrofitted to any existing system, making it a truly attractive option for every extrusion plant.

How you benefit:

- Vacuum pump control makes air supply unnecessary

- More stable vacuum using improved cyclones and frequency-controlled cyclone pumps

- Noise level cut in half

- Remote maintenance via Ethernet or SIM card

etc. AND ENERGY SAVINGS OF UP TO 90%

GESS.basic – The perfect retro fit kit

The Exelliq Group has developed a simple, cost-effective energy-saving system for lines without PLC control (TEC.LINE and RED.LINE basic). GESS. basic is operated using an easy-to-use touchscreen. The vacuum pumps and cyclone pumps of the calibration table can be controlled in automatic mode with set values. Therefore, the desired vacuum values are no longer reached by opening the bleeding valves but through controlled energy-saving regulation of the pumps.

How you benefit:

- The desired vacuum values can be easily set

- Less noise

- Can be retrofitted to existing lines

- Easy to use

- Haul-off possible through touchscreen

- Can be operated using mobile app